What Makes High Precision Mold Components So Important?

The demand for high-quality, durable products is at an all-time high. To meet this demand, manufacturers increasingly rely on high precision mold components. These components are essential in ensuring that products are produced with the utmost accuracy and consistency. But why are high precision mold components so important? Let’s explore the key reasons and how they contribute to a more efficient and cost-effective manufacturing process.

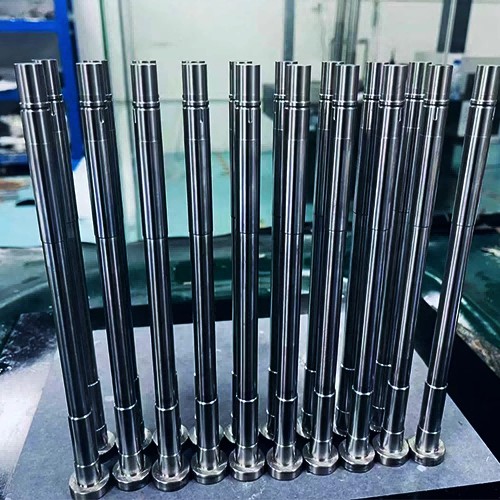

Ensuring Tight Tolerances and Product Accuracy

One of the primary advantages of high precision mold components is their ability to maintain tight tolerances. Molding processes often involve intricate designs, and the slightest deviation can lead to defects. Precision mold components are engineered to meet these exact specifications, ensuring that the final product is accurate and reliable. This is crucial, especially for industries where even minor inaccuracies can have significant consequences, such as aerospace, medical devices, and electronics.

Enhancing Production Efficiency

The use of high precision mold components can significantly improve production efficiency. These components are designed to perform consistently, reducing the likelihood of defects or malfunctions during the manufacturing process. As a result, manufacturers can maintain smooth operations, minimize downtime, and increase output. With precision components, the entire molding process becomes faster and more predictable, leading to faster time-to-market for products.

Reducing Waste and Material Costs

In the manufacturing world, waste is costly. Precision components help minimize material waste by ensuring that the molding process is accurate and efficient. When molds are made with high precision mold components, the parts produced fit perfectly with minimal adjustments needed. This reduces the need for costly reworks and excess material usage, ultimately lowering production costs and increasing profitability.

Improving Durability and Longevity of Molds

High precision mold components not only enhance the quality of the molded parts but also improve the longevity of the molds themselves. Molds made from precision components are less likely to wear down quickly, which means they can be used for longer periods without requiring extensive maintenance or replacement. This extends the lifecycle of the entire molding system, reducing long-term operating costs.

Meeting Industry Standards and Compliance

In many industries, such as medical, automotive, and electronics, precision is not just a matter of quality; it's a matter of compliance. Precision mold components are manufactured to meet stringent industry standards, ensuring that products are safe, reliable, and meet regulatory requirements. By using these components, manufacturers can avoid costly compliance issues and ensure their products are market-ready.

Customization for Complex Designs

With custom high precision mold components, manufacturers can create parts with complex shapes and intricate designs that would be difficult, if not impossible, to achieve with standard components. This opens up a wide range of possibilities for innovation, allowing businesses to push the boundaries of what is possible in product design. Whether it’s a highly detailed medical device or a precise automotive part, custom precision components provide the flexibility needed for diverse applications.

The importance of high precision mold components cannot be overstated. From ensuring tight tolerances and enhancing production efficiency to reducing waste and improving mold durability, these components are integral to modern manufacturing processes. Investing in high precision mold components not only helps manufacturers produce higher-quality products but also drives long-term cost savings and operational efficiency. As industries continue to evolve, the role of precision in manufacturing will only become more critical, making high precision mold components a key factor in staying competitive in today’s fast-paced market.

high precision mold components precision mold components custom high precision mold components