Why Precision Mold Components Matter More Than You Think?

In high-speed manufacturing, it’s often the smallest parts that have the biggest impact. Have you ever faced problems like:

Mold wear and tear after just a few production cycles?

Deformed or incomplete molded parts?

Constant mold adjustments and long downtimes?

Rising maintenance costs with no clear solution?

The root cause of these issues is frequently overlooked:

Low-quality or generic mold components.

What Are Precision Mold Components – and Why Should You Care?

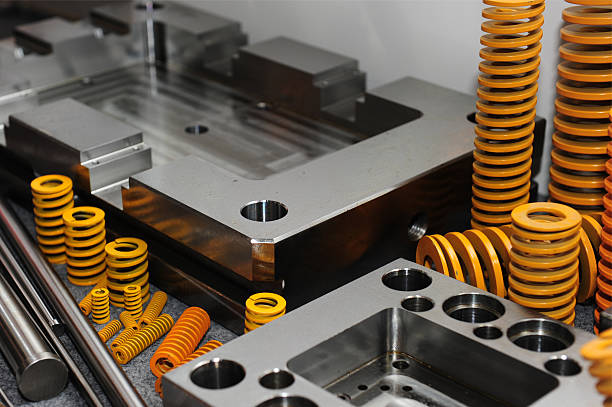

They may look insignificant — things like ejector pins, core inserts, guide pillars, sleeves, bushings — but they’re the heart of your mold system.

Manufactured to micron-level tolerances, precision mold components ensure:

Consistent product dimensions

Long mold lifespan

Smooth production with fewer defects

Ignore them, and you risk downtime, waste, and customer complaints. Choose them wisely, and you get performance, profit, and peace of mind.

Are You Using the Right Mold Parts?

Common Mistakes:

❌ Choosing molds based on price without checking the component quality

❌ Replacing customized parts with standard ones, causing fit and alignment issues

❌ Skipping proper surface treatments, resulting in faster wear and tear

What You Should Do Instead:

✅ Partner with a supplier who specializes in custom mold components

✅ Ensure parts meet strict material and dimensional standards

✅ Match every component to your mold’s structure and intended application

Industries That Rely on High-Precision Mold Components

From mass production to medical-grade manufacturing, top industries choose precision mold parts because failure is not an option:

Automotive: For high-wear, high-tolerance engine and lighting components

Medical: Where zero-defect and hygiene compliance are non-negotiable

Consumer Electronics: Ultra-miniature components demand exact fit

Industrial Equipment: Long-lasting, heavy-duty performance under load

What We Offer:

✅ Micro-tolerance machining (CNC + EDM)

✅ Custom parts made to your design specs

✅ Premium materials like H13, SKD61, and tungsten carbide

✅ Heat treatment, polishing, PVD coating & more

✅ Full quality control: hardness testing, inspection reports, material certificates

precision mold components custom mold parts injection mold tooling mold part supplier