High-Precision Mold Components: The Unsung Heroes of Quality Production

precision and quality are non-negotiable. The final product's excellence often hinges on components that many might overlook — the mold parts. Among these, high-precision mold components play a pivotal role in ensuring that products meet exact specifications, function flawlessly, and maintain consistency across mass production runs.

This article delves into why high-precision mold components are the unsung heroes behind superior manufacturing quality. We will also explore how custom precision mould parts manufacturing and reliable partnerships with leading precision mold parts suppliers such as Hairong can elevate your production processes. Additionally, we highlight the value of customized mould inserts and components tailored specifically to your project needs.

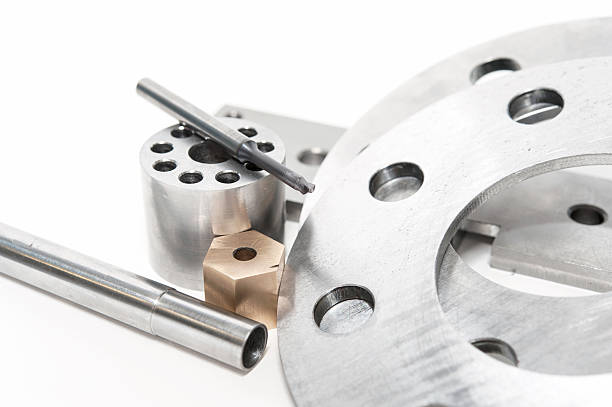

What Are High-Precision Mold Components?

High-precision mold components refer to the finely engineered parts used to form molds that shape, cut, or stamp materials into desired products. These components must be manufactured to extremely tight tolerances, often within microns, to ensure the mold performs consistently without defects or variations.

Typical components include:

Mold bases

Inserts

Cores and cavities

Guide pins and bushings

Ejector pins

Cooling channels

Each part must align perfectly and withstand intense pressure, temperature, and wear during the molding process. Even minor deviations can cause dimensional inaccuracies, surface defects, or reduced tool life.

Why Are High-Precision Mold Components Critical for Quality Production?

Accuracy Ensures Product Consistency

When mold components are produced with high precision, the molded products replicate the intended design accurately. This precision is crucial for industries such as automotive, aerospace, electronics, and medical devices, where strict standards and tolerances must be met.Improved Tool Life and Reduced Maintenance

High-quality mold components resist wear and tear better, reducing downtime for repairs or replacements. This leads to more efficient production schedules and lower maintenance costs over the mold’s lifespan.Enhanced Surface Finish and Functionality

Precision mold parts ensure smooth mold operation and better surface finish of molded items, reducing or eliminating the need for additional post-processing.Higher Production Speeds

With precision parts that fit and function perfectly, molding machines can operate at higher speeds without compromising quality, thus increasing throughput and reducing unit costs.

Custom Precision Mould Parts Manufacturing: Tailoring Solutions to Your Needs

Every manufacturing project has unique requirements, from product geometry to material and production volume. This is where custom precision mould parts manufacturing becomes indispensable.

Customized manufacturing allows engineers to design and fabricate mold components that perfectly fit specific molds and production conditions. It offers benefits such as:

Optimized design for complex parts that standard components cannot accommodate

Material selection tailored to withstand specific operational stresses or corrosion environments

Incorporation of innovative features such as conformal cooling channels for faster cycle times

Choosing the Right Precision Mold Parts Suppliers

Partnering with experienced precision mold parts suppliers is key to securing components that meet your quality standards and deadlines. Top-tier suppliers offer:

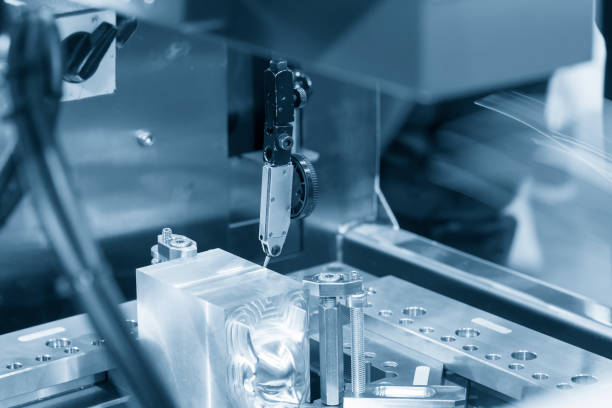

Advanced CNC machining capabilities ensuring micron-level tolerances

Strict quality control processes including CMM inspection and surface treatment

Ability to work with a variety of metals and alloys

Fast turnaround and flexible order quantities

Hairong stands out as a leading supplier by combining decades of expertise, cutting-edge technology, and customer-focused service to provide dependable mold parts tailored to your application.

Customized Mould Inserts and Components: Enhancing Mold Performance

Among the most critical parts are customized mould inserts and components. These inserts form the actual cavities that shape your product and must be engineered for precision and durability.

Advantages of customized inserts include:

Ability to adapt to design changes without overhauling the entire mold

Incorporation of special surface coatings or treatments to extend lifespan

Enhanced heat dissipation features to improve molding cycle times

Precision fitting to reduce flash and improve mold sealing

By working with a manufacturer like Hairong, you ensure your mould inserts are crafted with the latest technology and highest standards, resulting in superior product quality and operational efficiency.

Hairong: Your Trusted Partner in High-Precision Mold Components

With an extensive portfolio in custom precision mould parts manufacturing, Hairong has built a reputation for excellence among manufacturers worldwide. Their commitment to precision engineering, customer collaboration, and continuous innovation positions them as a reliable precision mold parts supplier.

Hairong’s expertise covers a wide range of industries including automotive, electronics, consumer goods, and medical devices. Their custom solutions — from high-tolerance mold components to complex inserts — enable clients to meet stringent production demands without compromise.

Summary:

In manufacturing, the importance of high-precision mold components cannot be overstated. These components are the foundation of product quality, influencing every aspect of the molding process from accuracy to efficiency.

By leveraging custom precision mould parts manufacturing and partnering with trusted precision mold parts suppliers like Hairong, manufacturers can unlock superior product consistency, longer tool life, and faster production cycles. Additionally, investing in customized mould inserts and components tailored to your specific needs ensures that your molds perform optimally throughout their lifespan. Ultimately, while these mold components may be the “unsung heroes,” their impact on quality production is profound and indispensable.

high-precision mold components custom precision mould parts manufacturing