Why Hairong Mold Inserts Are the Smart Choice for Precision Injection Molding?

Mold inserts have revolutionized the world of precision molding, offering manufacturers greater design flexibility, cost efficiency, and faster production cycles. Whether you're producing complex plastic parts for automotive, medical, electronics, or consumer goods, choosing the right mold inserts can make or break your manufacturing success.

In this article, we’ll explore why Hairong Mold Inserts stand out in the industry and how they can elevate your molding processes.

What Are Mold Inserts?

Mold inserts are detachable, precision-machined components placed into the mold base to form part of the cavity or core. These inserts allow for quicker part modifications, easy replacement, and reduced mold costs, especially in high-volume or multi-cavity production.

Why Use Mold Inserts?

In modern manufacturing, mold inserts offer a range of benefits:

Customization: Custom mold inserts can be tailored for different part geometries and materials.

Maintenance Efficiency: Replace worn inserts instead of the entire mold.

Versatility: Swap inserts to produce different products using a single mold base.

Precision Engineering: Perfect for fine-tolerance components like gears, micro-plastics, and optical parts.

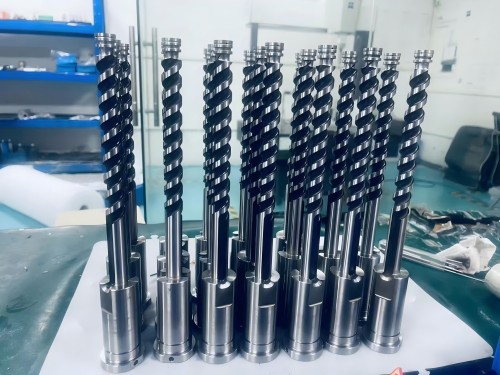

Hairong: A Trusted Manufacturer of Precision Mold Inserts

With years of engineering expertise and state-of-the-art manufacturing facilities, Hairong has become a trusted name in the mold insert industry. Their high-quality inserts are designed for use in demanding applications across diverse sectors.

Why Choose Hairong Mold Inserts?

Superior Materials

Hairong uses premium tool steels like H13, S136, and P20 to ensure durability, heat resistance, and long lifespan.

Tight Tolerance Machining

Hairong offers precision mold inserts with tolerances up to ±0.005mm, ideal for tight-fitting and high-performance components.

Custom Solutions

Whether you're producing complex electronics casings or auto parts, Hairong can deliver custom mold inserts that meet your exact specifications.

Faster Lead Times

Thanks to CNC automation and a streamlined process, Hairong delivers products with shorter lead times without compromising quality.

Competitive Pricing

By optimizing production costs and sourcing materials in bulk, Hairong provides competitive rates for injection molding inserts without sacrificing performance.

Applications of Hairong Mold Inserts

From mass production to prototyping, Hairong’s mold inserts serve a wide range of industries:

| Industry | Use Case Examples |

|---|---|

| Automotive | Dashboard components, gear wheels, fasteners |

| Medical | Syringe parts, inhaler casings, surgical tools |

| Electronics | Connector housings, LED frames, PCB enclosures |

| Consumer Goods | Cosmetic containers, mobile accessories |

Key Features of Hairong Mold Inserts

Interchangeable Designs: Easily swap out insert components to modify designs or repair tools.

Surface Treatment Options: Hairong offers nitriding, polishing, and PVD coatings to enhance wear resistance.

Thermal Management: Inserts designed with cooling channels to reduce cycle time and maintain dimensional stability.

Compatibility: Custom-fit inserts for both domestic and international mold bases.

How Mold Inserts Improve Production Efficiency

Implementing precision mold inserts can dramatically streamline your manufacturing workflow:

Reduced Downtime: If an insert wears out or breaks, you only replace that specific piece.

Lower Cost Per Part: Especially for high-volume orders, inserts minimize tool wear and mold maintenance costs.

Greater Design Freedom: Make quick design changes without replacing the entire mold.

Improved Quality: Consistent cavity quality leads to fewer rejects and tighter quality control.

Working with Hairong

Hairong partners with OEMs and mold makers worldwide to deliver consistent quality and technical support. Their engineers work closely with clients to understand needs, propose solutions, and provide full DFM (design for manufacturing) support.

Whether you're starting a new project or upgrading an existing mold system, Hairong's experienced team will ensure your precision mold inserts are optimized for performance, longevity, and cost.

Ordering & Logistics

Hairong ships globally with robust packaging standards to prevent insert damage during transit. All products undergo a thorough quality inspection before delivery.

Additional services include:

3D drawings & CAD support

Material certification (RoHS, REACH compliance)

Rapid prototyping for urgent projects

Expert Tips for Choosing the Right Mold Inserts

Before selecting mold inserts, consider these factors:

Material Compatibility: Choose the right insert steel based on the plastic material and part geometry.

Tolerance Needs: For precision applications, tighter tolerances ensure better fit and finish.

Production Volume: Higher volumes may benefit from hardened inserts with special coatings.

Cooling Needs: Ensure inserts allow for proper heat dissipation to prevent warping.

Investing in the right mold inserts is essential for long-term manufacturing success. Hairong Mold Inserts deliver the reliability, customization, and precision that industries demand today. Whether you're scaling up production or refining complex designs, Hairong's commitment to quality and innovation makes them the ideal partner. If you’re looking for custom mold inserts, injection molding components, or precision mold insert manufacturers, Hairong offers the performance, support, and pricing you need.

custom mold inserts precision mold inserts injection molding components.