How Do Custom Precision Mould Parts Improve Injection Molding Efficiency?

Manufacturers worldwide are under constant pressure to reduce cycle times, minimize defects, and meet increasingly tight tolerances. One of the most critical factors influencing all these aspects is the quality and customization of precision mould parts. At Hairong, we specialize in manufacturing high-performance custom precision mould parts that optimize the injection molding process. In this article, we’ll explore how these customized components can significantly enhance molding efficiency, reduce operational costs, and improve product quality.

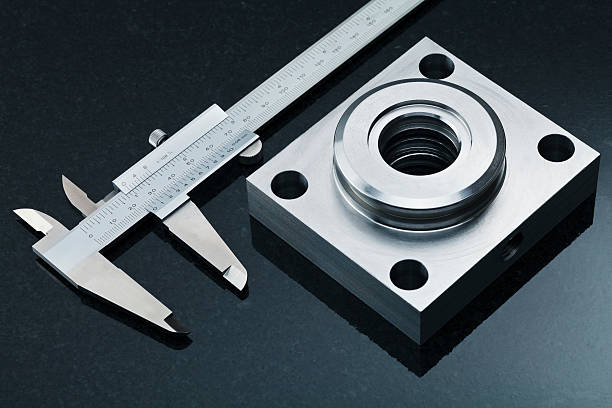

What Are Custom Precision Mould Parts?

Custom precision mould parts refer to mold components—such as cores, cavities, ejector pins, sleeves, sliders, and lifters—manufactured to exacting specifications based on specific mold designs or end-use requirements. Unlike standard off-the-shelf components, custom parts are tailored for each mold, ensuring perfect alignment, minimal friction, and optimal performance.

These parts often belong to a broader category of precision injection mold parts, which include:

Mold inserts and core pins

Interchangeable cavity blocks

Gate bushings

Precision die components

Custom ejector systems

Hairong’s strength lies in delivering these parts with high dimensional accuracy (±0.002mm), superior surface finish (Ra<0.4), and advanced material treatment for durability.

1. Improved Tolerances = Fewer Defects

Injection molding is all about repeatability. If the mold components are not precisely manufactured or properly aligned, the resulting parts can suffer from flash, short shots, warping, or dimensional instability. Using custom precision mould parts, especially those made with CNC and EDM technologies, ensures:

High dimensional accuracy

Better mold alignment

Uniform clamping pressure

Reduction in rework or scrap rate

2. Faster Cycle Times with Optimized Cooling Channels

One of the most overlooked aspects of mold performance is cooling efficiency. Custom-made components allow for the integration of optimized water lines, baffles, and conformal cooling channels inside the mold core and cavity blocks.

With precision injection mold parts designed for better thermal regulation:

Cooling time is reduced

Cycle time is shortened

Warping or sink marks are minimized

3. Enhanced Durability and Wear Resistance

Custom parts are often made from tool steels like H13, SKD61, S136, and even carbide or beryllium copper, depending on the application. Through advanced heat treatment and surface coating (e.g., nitriding, PVD, TiN), these parts offer:

Longer tool life

Resistance to abrasive fillers

Reduced maintenance frequency

Stable performance under high pressure or temperature

For manufacturers running long production cycles, precision die components with enhanced wear resistance mean more uptime and fewer interruptions for part replacement.

4. Easy Maintenance and Interchangeability

When components are customized and modular, mold maintenance becomes faster and less costly. Hairong specializes in interchangeable precision mould parts, allowing mold technicians to replace only the worn part (e.g., a core pin or ejector) instead of disassembling the entire mold.

This modularity:

Saves valuable machine time

Reduces labor costs

Improves long-term ROI of the mold system

Furthermore, consistent documentation and serialization of custom parts make future maintenance or reordering simple and efficient.

5. Industry-Specific Optimization

Every industry has different molding requirements. For example:

Automotive parts require high strength and tight tolerances

Medical applications demand cleanroom-compliant components

Electronics parts need micro-tolerance mold inserts and mini ejector pins

Hairong provides custom precision mould parts tailored to these unique demands. We work closely with OEMs, mold makers, and engineering teams to deliver solutions that are:

ISO-compliant

Fully traceable

Application-specific

This level of specialization not only improves efficiency but also ensures compliance and customer satisfaction.

Hairong: Your Trusted Partner in Precision Mould Engineering

Hairong has been a leading supplier of precision die components and custom mold parts for over a decade. With state-of-the-art CNC, EDM, WEDM, and grinding capabilities, we serve clients across industries—from automotive and medical to electronics and consumer goods.

Our key strengths include:

Tolerances up to ±0.002mm

In-house design assistance

Fast prototyping and mass production

Surface finish options up to mirror polishing

Worldwide shipping and technical support

Whether you need precision injection mold parts for a new project or want to upgrade your existing molds, Hairong offers fast, flexible, and reliable solutions.

Conclusion: Customization is the Future of Molding

In today’s competitive manufacturing environment, one-size-fits-all simply doesn’t cut it. Investing in custom precision mould parts not only boosts injection molding efficiency but also contributes to better quality, reduced cycle time, and increased operational longevity. With the right partner like Hairong, manufacturers can transform their production performance from average to exceptional.

precision injection mold parts custom precision mould parts precision die components