What Tolerances Define Truly High Precision Cap Mold Parts?

For manufacturers aiming to produce consistent, defect-free bottle caps at scale, the quality and tolerance of mold components are non-negotiable. But what exactly defines “high precision” when it comes to cap mold parts?

In this article, we’ll dive into the critical tolerances that set high-precision mold components apart, why they matter for efficiency and product quality, and how Hairong—a trusted name in mold part manufacturing—meets and exceeds global expectations in bottle cap mold accessories.

Why Tolerance Matters in Bottle Cap Molding

Tolerance refers to the permissible limit of variation in a physical dimension. In injection molding, especially for plastic bottle caps, even a variation of 0.01 mm can impact the functionality and aesthetics of the final product.

Poorly aligned or loosely toleranced plastic bottle cap mold parts can result in:

Cap leaks or weak seals

Inconsistent cap threads

Deformation during ejection

Excessive wear on machinery

In contrast, high-precision cap mould accessories ensure smooth molding cycles, accurate part geometry, and high-speed production with minimal rejections.

Industry Standard Tolerances for Cap Mold Parts

For general injection mold tooling, standard tolerances might range between ±0.05 mm to ±0.1 mm. However, high precision cap mold parts used in high-speed beverage or pharmaceutical production lines require tighter tolerances, typically within:

±0.01 mm to ±0.02 mm for core pins, cavities, and inserts

±0.005 mm for critical sealing surfaces or threaded zones

<2 µm surface roughness for polished shut-off areas

These tolerances help maintain consistent wall thickness, superior thread clarity, and better closure fitting — all essential for large-volume, high-speed cap production.

How Hairong Achieves Ultra-Precise Tolerances

As a leading manufacturer of cap mould accessories, Hairong leverages a combination of advanced technologies, skilled engineering, and rigorous QC processes to deliver parts that meet ultra-precise tolerances. Here’s how we do it:

1. CNC Machining & EDM Precision

Hairong employs high-speed CNC machines with 5-axis capabilities and ultra-fine EDM to machine complex geometries with micron-level accuracy.

2. High-Quality Steel Materials

We only use high-grade tool steels (like H13, S136, and SKD61) to ensure dimensional stability and long mold life.

3. Strict Quality Inspection

Every component goes through CMM (Coordinate Measuring Machine) inspection and surface profiling to guarantee precision before shipping.

4. Mirror-Finish Polishing

For sealing areas and moving parts, we achieve sub-micron surface finishes to reduce friction and ensure proper part ejection.

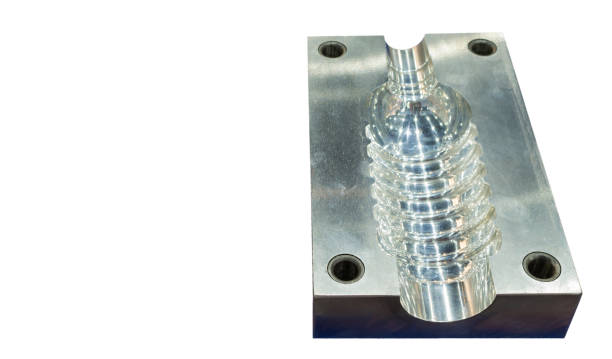

Common High Precision Bottle Cap Mold Accessories

Hairong offers a wide range of bottle cap mold accessories engineered with high precision. Some of the most requested include:

Core inserts & cavities for screw and snap-fit caps

Gate inserts for hot runner systems

Ejector pins and sleeves

Slides and lifters for flip-top cap molds

Thread-forming inserts

Alignment bushings and guide pins

Real-World Benefits of Tight Tolerances

Investing in high precision cap mold parts delivers long-term returns for mold owners and plastic processors. Here’s how:

✅ 1. Reduced Cycle Time

Tighter tolerances allow for faster injection and cooling cycles without quality trade-offs.

✅ 2. Better Cap Fit and Function

Accurate threads, sealing rings, and closures ensure the cap performs consistently on the bottle.

✅ 3. Minimized Flash and Burr

Precision machining significantly reduces excess plastic waste and trimming efforts.

✅ 4. Longer Mold Life

High-quality, well-fitting parts reduce wear, maintenance needs, and machine downtime.

Applications: From Beverage to Pharmaceuticals

Hairong’s plastic bottle cap mold parts are trusted across multiple industries, including:

Beverage packaging (PET bottle caps, sports drink closures)

Pharmaceutical vials and dropper caps

Personal care (shampoo, lotion flip caps)

Food-grade condiments and sauces

In all these applications, cap mould accessories with tight tolerances play a key role in ensuring safety, usability, and production efficiency.

Final Thoughts: Precision Is a Profitable Investment

If you're scaling your injection molding operations or entering a high-speed cap production line, settling for average-quality components is not an option. High precision cap mold parts aren’t just about manufacturing perfection—they’re about competitive advantage.

At Hairong, we specialize in manufacturing customized plastic bottle cap mold accessories with tolerances as low as ±0.005 mm. Whether you’re upgrading an existing mold or building a new one from scratch, we can help you meet your production and performance goals.

high precision cap mold parts bottle cap mold accessories cap mould accessories