High-Precision Mold Components: Unlocking Efficiency in Injection Molding

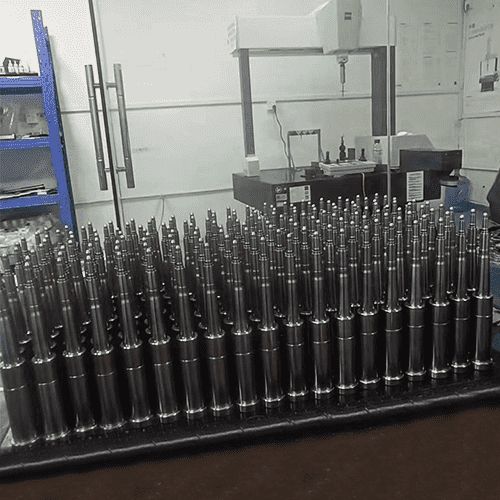

Nowhere is this more evident than in injection molding, where the demand for precise, repeatable results continues to rise. At the heart of this process lies a crucial, often overlooked element—high-precision mold components.

From custom mold inserts to intricate precision tooling parts, the quality and design of these components significantly impact not only the performance of the mold but also the consistency, cycle time, and lifespan of production. In this article, we’ll explore how high-precision mold components drive productivity, and why they’re indispensable for manufacturers aiming to scale quality and efficiency.

What Are High-Precision Mold Components?

High-precision mold components are tightly engineered parts used within a mold set for plastic injection molding. These include:

Core pins

Ejector pins

Cavity and core inserts

Sliders and lifters

Cooling channels

Gate bushings and sleeves

Manufactured using advanced CNC machining, EDM, and grinding technologies, these components are designed to meet micron-level tolerances and maintain dimensional stability under high temperature and pressure environments.

How Precision Impacts Injection Molding Efficiency

Efficiency in injection molding hinges on repeatability and minimal downtime. Here’s how precision mold parts contribute:

1. Reduced Cycle Time

Tightly toleranced mold components ensure smoother operation and alignment, which reduces friction, flash, and material waste. This translates to shorter injection cycles and increased throughput.

2. Consistent Product Quality

Precision in mold components eliminates variances in molded part dimensions. This leads to higher consistency in part output, reducing the need for rework or inspection bottlenecks.

3. Extended Mold Life

High-precision parts often come with hardened surfaces and optimized cooling designs, which reduce wear and thermal stress. Molds using these components tend to last longer and require less maintenance, improving overall ROI.

4. Minimized Downtime

Better-fit components mean fewer breakdowns and adjustments. Manufacturers benefit from stable production, especially for high-volume and high-tolerance parts such as in automotive, medical, or electronics industries

Applications of High-Precision Mold Components

From medical-grade device production to automotive interiors and consumer electronics, the demand for miniaturized, high-tolerance parts continues to grow. That’s where custom mold components excel—offering design flexibility, tight tolerances, and enhanced functionality.

Some use cases include:

Medical: Implantable devices, syringes, labware

Automotive: Precision clips, dashboards, sensor casings

Electronics: USB connectors, casings, switches

Packaging: Tamper-proof lids, multi-shot closures

Choosing the Right Supplier for Precision Mold Parts

Not all mold component suppliers are created equal. When selecting a partner, manufacturers should consider:

Material expertise: Tool steels, stainless steel, copper alloys, etc.

Tolerance capabilities: ±0.005 mm or better for critical fits

Surface finish control: For wear resistance and mold flow

Custom fabrication capabilities: CAD/CAM integration, reverse engineering

Quality control: ISO 9001, in-house CMM inspections, full traceability

A reliable supplier like Hairong provides fully customized high-precision mold components with guaranteed consistency, precision, and rapid turnaround to meet evolving project demands

Final Thoughts: Precision Equals Productivity

Investing in high-precision mold components is not just about better parts—it’s about system-wide efficiency. These components act as the foundation for consistent, high-quality output, enabling manufacturers to meet modern requirements for speed, complexity, and scalability.

As demand for customized injection molded products grows, businesses that prioritize precision mold tooling will gain a distinct advantage in both quality and cost-efficiency.

high-precision mold components custom mold components precision tooling parts