Precision Mould Parts – The Precision Core & Selection Guide for Industrial Manufacturing

Introduction: Why Are Precision Mould Parts the "Invisible Cornerstone" of Modern Manufacturing?

In high-end manufacturing sectors such as automotive components, electronic devices, and medical equipment, "precision" is the core standard that determines product quality and market competitiveness. The key to upholding this standard lies in Precision Mould Parts. From the guiding and positioning of moulds to the detailed control of injection moulding, the tolerance, material, and performance of every precision part directly impact the mould’s service life (which can be extended by over 30% on average), production efficiency (reducing scrap rates by 15%-20%), and the consistency of the final product.

This article systematically analyzes the core types, key selection factors, industry application scenarios of precision mould parts, and how to enhance the stability of manufacturing processes through high-quality parts – providing practical references for manufacturing buyers, mould engineers, and factory managers.

I. What Are Precision Mould Parts? Analysis of Core Types & Functions

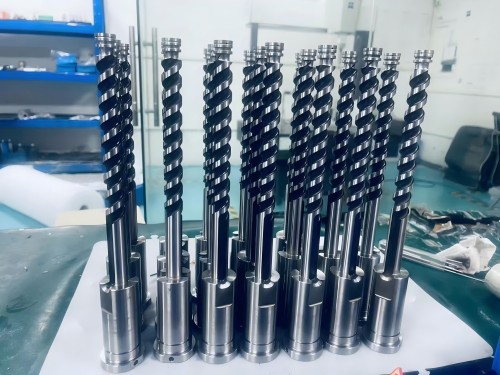

Precision Mould Parts refer to high-precision components used in mould systems to achieve key functions such as positioning, guiding, ejection, and cooling, with dimensional tolerances controlled within the range of ±0.001mm to ±0.01mm. Their core value lies in ensuring "macro production stability" through "microscopic precision". The common types and their functions are as follows:

II. How to Select? 5 Key Factors Affecting the Performance of Precision Mould Parts

For buyers and engineers, incorrect selection may lead to frequent mould failures (such as guide pin wear and ejector pin breakage), reduced production efficiency, or even mass product scrapping. The following 5 factors are the core basis for selection:

1. Material: Choose "Wear-Resistant" or "Impact-Resistant" Materials Based on Working Conditions

2. Precision Grade: Match Product Requirements to Avoid "Excessive Precision" Cost Waste

3. Surface Treatment: A "Protective Layer" to Enhance Wear Resistance and Corrosion Resistance

4. Size & Specification: Follow the "Mould Compatibility" Principle

5. Supplier Qualification: Prioritize Partners with "ISO Certification + Customization Capability"

III. Industry Applications: Practical Cases of Precision Mould Parts in 3 Core Fields

Different industries have significant differences in the demand for precision mould parts. The following cases can help you understand the selection logic more intuitively:

1. Automotive Manufacturing: High-Temperature Resistance and Impact Resistance Are Core Requirements

Application Scenario: Moulds for automotive engine plastic parts (such as intake pipes)

Core Parts: Cooling inserts (material: SKD61, nitrided) and large guide pins (diameter: 30mm, tolerance: ±0.005mm)

Selection Reason: The forming temperature of engine parts is high (about 280℃), and the high-temperature resistance of SKD61 can prevent insert deformation; the guide pins need to withstand the high-frequency impact of mould opening and closing, and the high coaxiality design can reduce wear.

2. Electronic Equipment: Ultra-Precision and Corrosion Resistance Are Key

Application Scenario: Moulds for mobile phone charger interfaces

Core Parts: Core pins (material: SKH51, PVD-coated) and stainless steel guide bushings (SUS440C)

Selection Reason: The aperture tolerance requirement of the interface is ±0.002mm, and the high hardness of SKH51 can ensure that the core pin does not wear after long-term use; the charger needs to be in contact with current, and the rust resistance of the stainless steel guide bushing can avoid short-circuit risks.

3. Medical Devices: Sterility and High Consistency Are the Bottom Line

Application Scenario: Moulds for syringe barrels

Core Parts: Ejector pins (material: SUS440C, polished) and cooling inserts (thermal conductivity: 50W/(m·K))

Selection Reason: Medical devices need to comply with FDA standards, and the corrosion resistance of SUS440C can prevent the precipitation of metal ions; the cooling insert needs to cool down quickly to ensure that the inner wall of the syringe barrel is smooth and free of bubbles.

IV. Frequently Asked Questions (FAQ): Solving Pain Points in the Purchase and Use of Precision Mould Parts

Q1: When precision mould parts are worn, do they have to be replaced?

A1: It depends on the degree of wear. If the wear causes the product size to exceed the tolerance (such as guide pin clearance > 0.005mm), replacement is mandatory; if there are only slight surface scratches, repair can be done through polishing (e.g., Ra ≤ 0.4μm) to extend the service life by 1-2 months.

Q2: What is the usual delivery time for customized non-standard Precision Mould Parts?

A2: It depends on the material and complexity. For simple non-standard parts (such as ejector pins of special lengths) made of ordinary materials (such as SKD61), the delivery time is about 7-10 days; for parts made of special materials (such as SKH51) or with complex structures (such as special-shaped cooling inserts), it takes 15-20 days.

Q3: How to judge whether the precision of the parts provided by the supplier meets the standard?

A3: Request the supplier to provide a coordinate measuring machine (CMM) inspection report (to test dimensional tolerance, coaxiality, etc.), or conduct self-inspection with tools: use a micrometer to measure diameter tolerance (precision: 0.001mm) and a roughness tester to measure surface roughness (Ra value).

Conclusion: Choosing High-Quality Precision Mould Parts Means Choosing "Manufacturing Stability"

Precision Mould Parts Precision Mould Parts selection guide high-quality Precision Mould Parts