How Do Precision Mold Components Improve Manufacturing Accuracy?

Achieving high precision and consistent quality is no longer optional—it is critical. Manufacturers across industries rely heavily on molds to produce accurate, repeatable, and defect-free parts. Here, precision mold components play a pivotal role in ensuring product quality and operational efficiency. Hairong, a leading provider of high-quality mold solutions, offers a comprehensive range of high-precision mold components and custom mold components that optimize production processes and enhance manufacturing accuracy.

Understanding Precision Mold Components

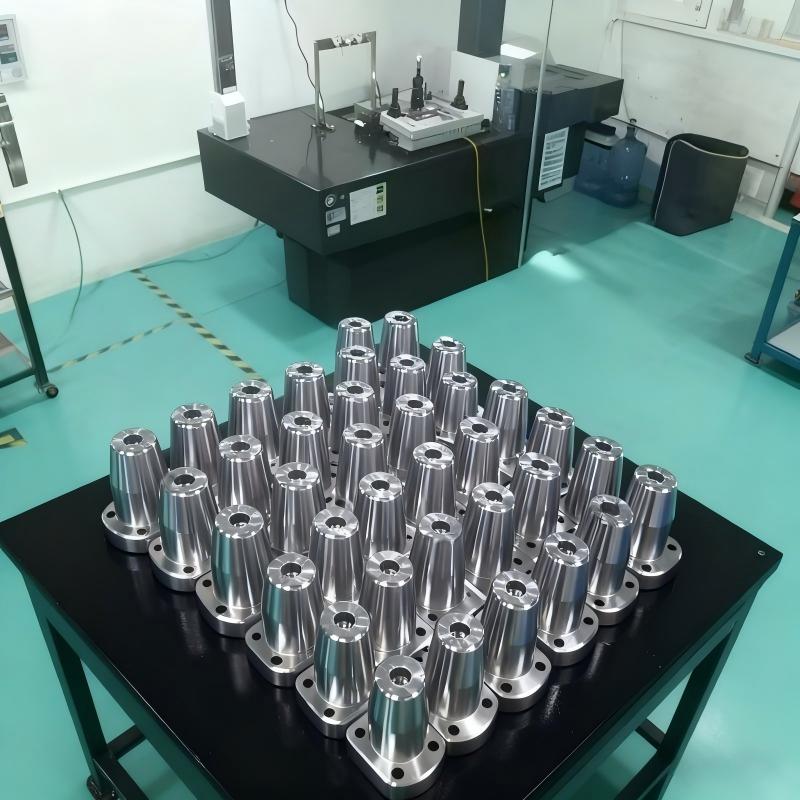

Precision mold components refer to parts used in molds that adhere to strict tolerances and design specifications. These components include mold bases, ejector pins, guide pins, inserts, cores, and cavities. By maintaining tight dimensional accuracy, these parts ensure that each molded product is uniform and meets engineering requirements.

Key types of components include:

Precision mold parts: Standardized components with reliable tolerances for general applications.

High-precision mold components: Advanced parts for critical applications requiring extreme accuracy.

Custom mold components: Tailored components designed to meet unique product specifications or complex geometries.

The choice of component material—typically high-grade tool steel, hardened alloys, or stainless steel—combined with advanced manufacturing techniques such as CNC machining, EDM (Electrical Discharge Machining), and surface treatment, ensures long-lasting performance and minimal wear.

How Precision Mold Components Enhance Manufacturing Accuracy

1. Consistent Product Quality

In mass production, even minor deviations in mold geometry can result in significant defects. High-precision mold components maintain exact dimensions and alignment within the mold, ensuring that every part produced matches design specifications. This consistency reduces scrap rates, improves assembly accuracy, and strengthens overall product reliability.

2. Reduced Tolerance Errors

Complex products, especially in automotive, electronics, and medical devices, require molds with extremely tight tolerances. Custom mold components allow manufacturers to achieve precise clearances and cavity dimensions, minimizing deviations caused by material shrinkage, thermal expansion, or wear.

3. Optimized Production Efficiency

Precision components reduce downtime associated with mold adjustments, maintenance, and part rejection. By integrating high-precision mold components and custom mold components, manufacturers can streamline operations, shorten cycle times, and achieve higher throughput without sacrificing quality.

4. Extended Mold Lifespan

Durable, precisely engineered mold components experience less wear and deformation over time. This prolongs the life of molds, reduces the frequency of replacements, and lowers overall production costs. Hairong uses high-strength materials and precision machining to ensure components maintain performance under high-volume production conditions.

5. Support for Complex Designs

Modern products often feature intricate geometries and tight interlocking features. Standard mold components may not provide the necessary accuracy. Custom mold components enable manufacturers to achieve detailed designs, allowing for innovative product development and faster market entry.

Applications Across Industries

1. Automotive Manufacturing

Precision mold components are used in producing high-tolerance engine parts, interior fittings, and safety-critical components. High-quality molds ensure parts fit seamlessly, enhancing vehicle performance and safety.

2. Electronics & Consumer Devices

Molds for connectors, housings, and precision mechanical parts demand exacting tolerances. Using high-precision mold components, manufacturers reduce assembly errors and product failures.

3. Medical Devices & Pharmaceuticals

Medical components require molds with extreme precision and hygiene standards. Hairong’s custom mold components meet stringent requirements, ensuring compliance with regulatory standards.

4. Industrial & Packaging Equipment

Plastic parts for industrial machinery and packaging applications rely on molds that produce consistent, dimensionally stable parts. Precision mold parts improve operational efficiency and reduce waste.

Industry Insights: Why Precision Matters

Studies show that minor dimensional errors in molds can result in rejection rates as high as 15% in mass production, leading to significant material waste and cost overruns.

With global competition driving demand for zero-defect production, investing in high-precision mold components is now a strategic necessity, not a luxury.

Advanced manufacturing techniques such as 5-axis CNC machining, laser scanning, and automated inspection have enabled tighter tolerances and improved reliability in custom mold components.

Why Choose Hairong?

Hairong is a trusted provider of precision mold parts, high-precision mold components, and custom mold components. With decades of experience in the mold manufacturing industry, Hairong delivers:

High-quality materials and advanced machining technology for durability and accuracy.

Custom solutions tailored to complex product designs and industry-specific requirements.

Comprehensive support, from design consultation to delivery, ensuring clients achieve maximum efficiency and minimal defects.

By partnering with Hairong, manufacturers can:

Improve production accuracy and repeatability.

Reduce material waste and operational costs.

Extend mold lifespan and maintain consistent product quality.

In conclusion, the right precision mold components are essential for modern manufacturing. Whether you need standardized parts or custom-engineered solutions, Hairong provides the expertise and quality required to enhance manufacturing accuracy and support long-term business success.

precision mold parts high-precision mold components custom mold components